Driveshaft collision repair is a critical aspect of fleet vehicle restoration, addressing structural damage that can impact performance and safety. A multi-step process involves inspection, disassembly, replacement of damaged parts, and final testing to ensure functionality and reliability. Regular maintenance, including timely checks, fluid changes, storage in optimal conditions, and prompt repair of damages, can prevent future collision repairs and extend vehicle lifespan.

In the realm of fleet vehicle maintenance, post-collision driveshaft damage is a prevalent challenge. When a fleet vehicle sustains a collision, the driveshaft—a crucial component for power transmission—often incurs significant stress, leading to intricate repair needs. This article guides through the intricacies of driveshaft collision repair, offering insights into identifying common types of damage, a step-by-step repair process, and best practices to prevent future issues. Mastering driveshaft collision repair is essential for fleet managers aiming to keep their vehicles on the road efficiently.

- Understanding Post-Collision Driveshaft Damage in Fleet Vehicles

- The Step-by-Step Process of Driveshaft Collision Repair

- Best Practices and Maintenance Tips for Future Prevention

Understanding Post-Collision Driveshaft Damage in Fleet Vehicles

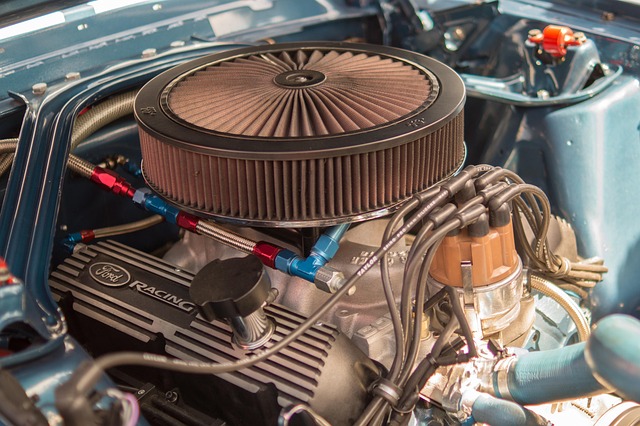

In the event of a collision, fleet vehicles sustain various types of damage, and driveshaft collision repair is often a critical aspect of restoration. Unlike car scratch repair or vehicle body repair, which primarily deals with external aesthetics, driveshaft issues can significantly impact the overall performance and safety of a fleet vehicle. The driveshaft, responsible for transmitting power from the engine to the wheels, is a sophisticated assembly that requires meticulous attention during repairs.

Post-collision damage may manifest as cracks, deformations, or complete failure of the driveshaft components, necessitating expert intervention. Identifying and addressing these issues promptly is crucial for ensuring the fleet’s operational efficiency and driver safety. Reputable repair facilities equipped with specialized tools and trained technicians are best suited to handle such intricate repairs, ultimately minimizing downtime and maximizing the vehicle’s longevity.

The Step-by-Step Process of Driveshaft Collision Repair

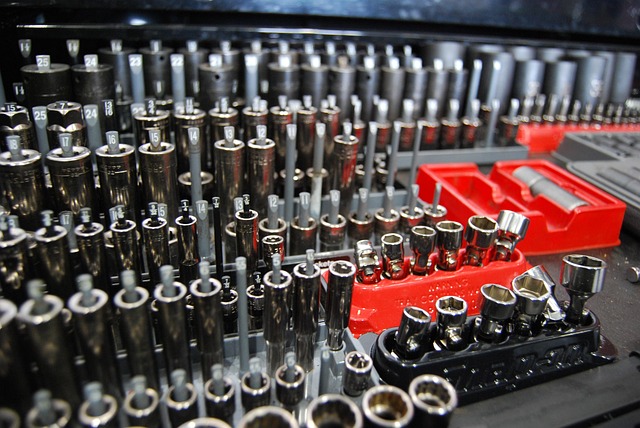

The process of driveshaft collision repair for fleet vehicles involves several meticulous steps to ensure safe and reliable operation. It begins with a thorough inspection to assess the extent of damage, including visual examination, road testing, and diagnostic scanning using specialized tools. This initial phase is crucial in identifying any hidden issues or component failures that could impact performance after repairs.

Once the evaluation is complete, the damaged driveshaft is carefully disassembled, allowing technicians to access and replace affected parts such as u-joints, yokes, and coupling seals. Each component is inspected for wear, damage, or contamination before replacement. After the necessary parts are installed, a test drive is conducted to verify the driveshaft’s functionality, torque transfer, and overall performance. This meticulous process guarantees that each vehicle returns to service in optimal condition, addressing both visible and latent damage from the collision, and ensuring safe and efficient operation for fleet vehicles on the road.

Best Practices and Maintenance Tips for Future Prevention

To prevent future driveshaft collision repairs for fleet vehicles, regular maintenance and adherence to best practices are paramount. One key tip is to ensure timely checks for any signs of damage or wear, focusing on high-risk areas like the drivetrain and suspension. Regular fluid changes and inspections can significantly reduce the likelihood of costly repairs down the line. These proactive measures not only extend the lifespan of your fleet vehicles but also contribute to safer operations on the road.

Additionally, proper storage and parking conditions play a crucial role in preventing driveshaft collision repair needs. Avoiding harsh weather conditions, uneven surfaces, or cramped spaces can help maintain the integrity of your vehicle’s underbody and drivetrain components. Regular car body repair and cosmetic touch-ups, such as fixing dents or scratches promptly, also contribute to overall vehicle health, ensuring that any potential issues are addressed before escalating into major problems.

In conclusion, proficient driveshaft collision repair is paramount for maintaining fleet vehicles’ safety and efficiency. By understanding common post-collision damage and implementing best practices, fleet managers can ensure swift and effective repairs. The step-by-step process outlined in this article serves as a valuable guide, emphasizing the importance of thorough inspection, accurate replacement parts, and proper alignment. Adhering to these maintenance tips will not only minimize driveshaft-related issues but also contribute to the overall longevity and performance of fleet vehicles, ultimately reducing operational costs and enhancing road safety.